Bill of Materials (BOM) Management ensures PLM users across the enterprise have access to accurate BOM data. It enables the management of complex BOMs with visibility and the opportunity to collaborate across multi-disciplined teams including internal, suppliers, and/or outsourced manufacturers.

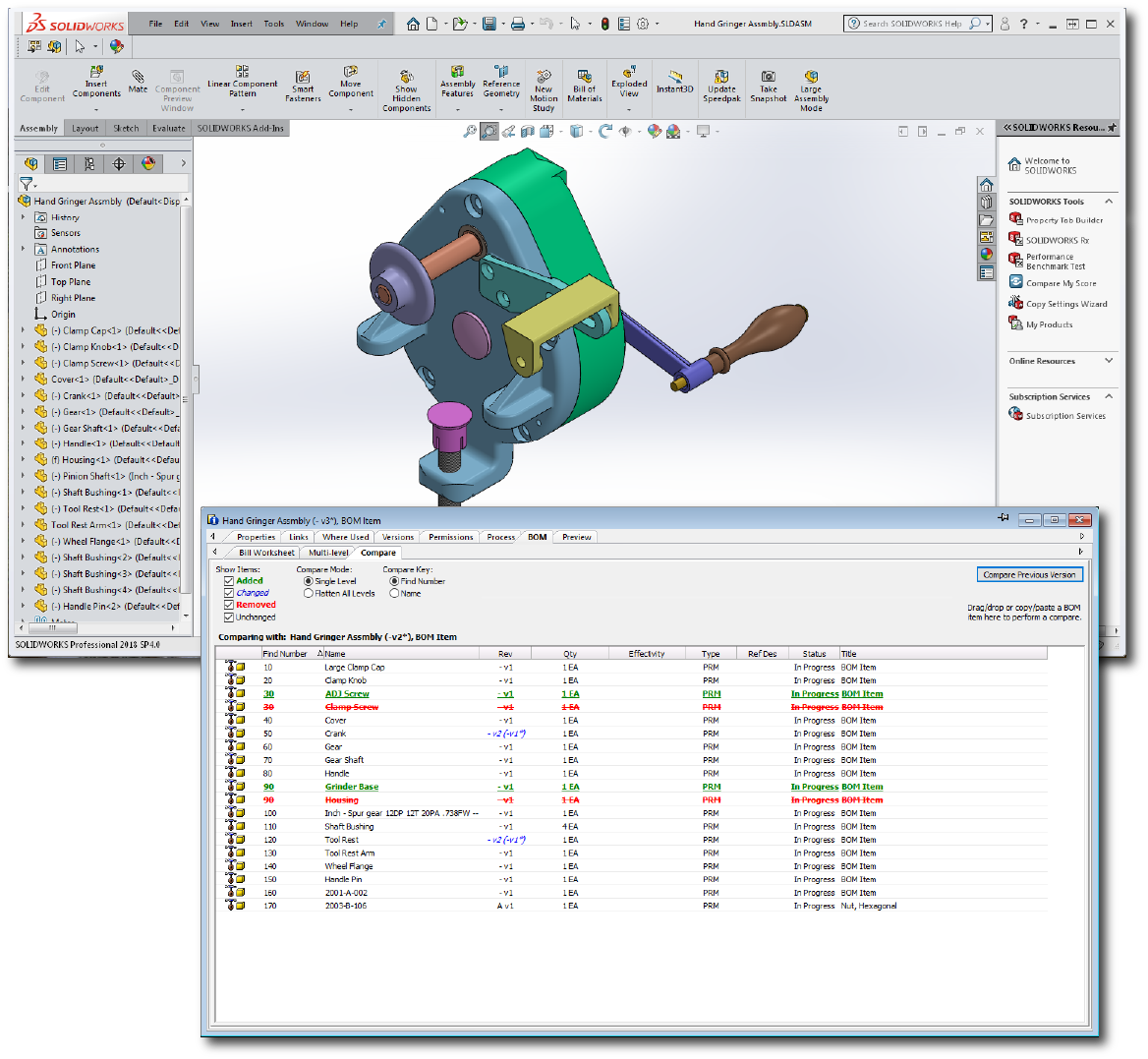

The ability to red-line and compare previous revisions or similar product builds allows for insight into changes and product configurations which leads to improved product quality.

Additionally, BOM Management allows for the management of alternate and/or substitute parts as well as the ability to perform BOM cost rollups and weight calculations, which helps companies reduce product costs, manufacturing errors, as well as scrap and rework.

Dynamic product design and product development processes are driving the need for visibility and management of multiple BOM views including as engineered, as built, as shipped and as serviced.