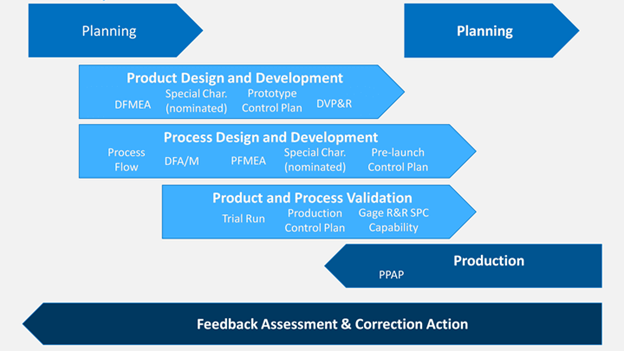

PLM provides the mechanism for managing the Advanced Product Quality Planning processes and procedures to support planning and programs, product design and development, product manufacturing processes, testing and validation, and lastly the product launch and continuous improvement.

The ability to implement and manage closed-loop corrective action and root cause analysis provides early insight into issues and the ability to identify affected items before product release.

Creating, storing and maintaining all of the critical quality documentation within PLM enables visibility, collaboration and streamlines the processes related to improving product development and process planning across the enterprise.