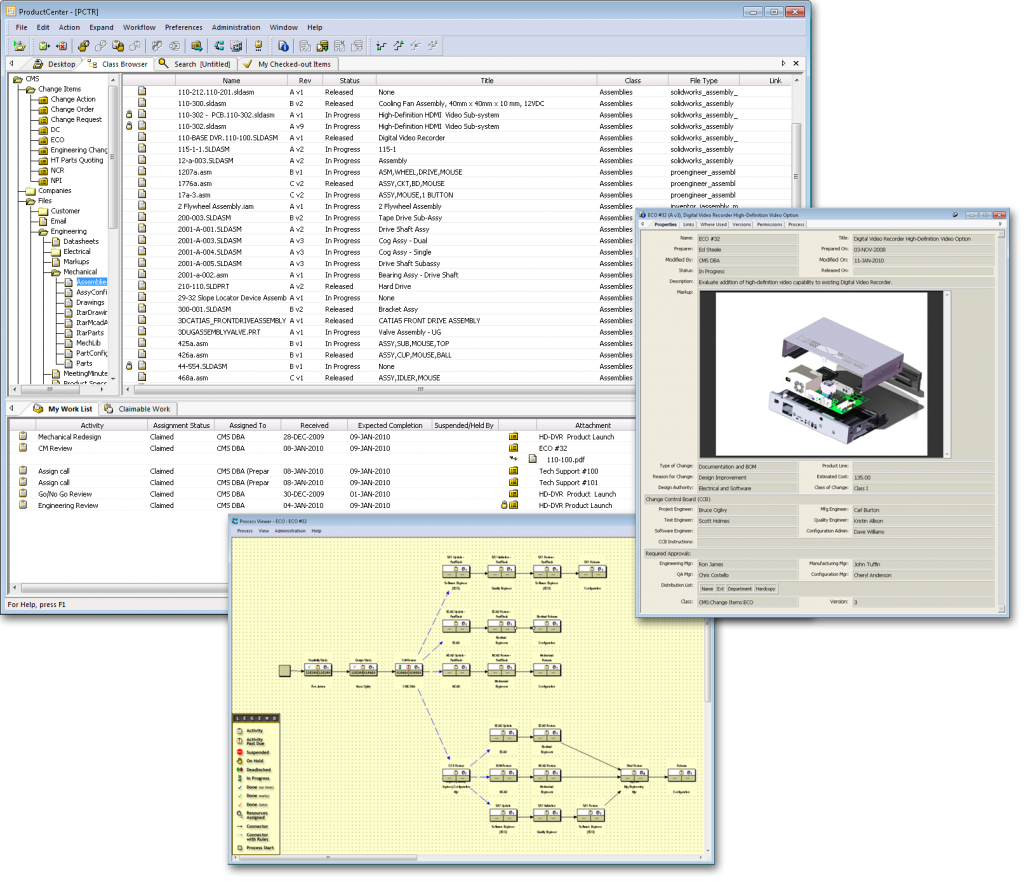

Product Lifecycle Management connects your people to work collaboratively and centralizes and improves the management of all your product data. It streamlines the process steps you employ to create, manufacture, and support your products — from the earliest glimmer of a concept through to retirement.

ProductCenter PLM is proven among many worldwide users and installs readily for immediate gains in product development efficiency. Improve your business results and join the hundreds of leading manufacturers that succeed — even in the toughest of market conditions — through use of ProductCenter PLM solutions.