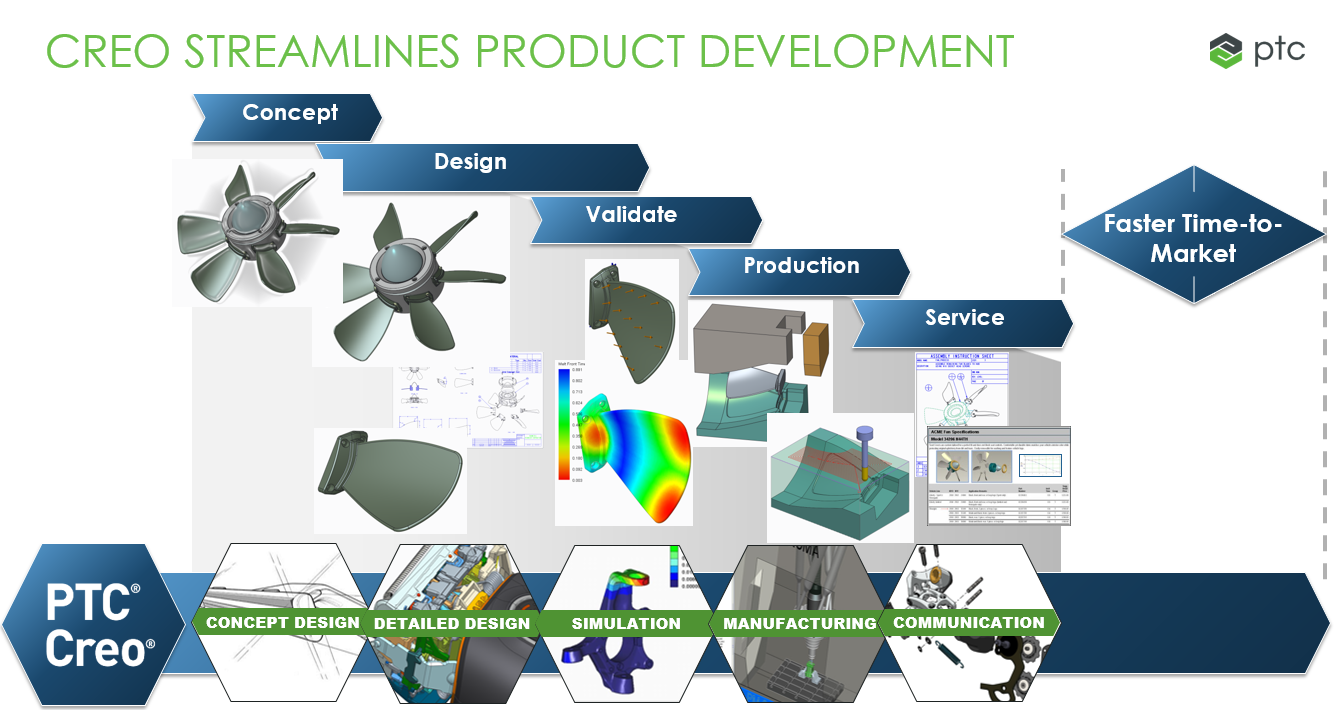

Creo is a comprehensive suite of integral CAD/CAM/CAE and CAID solutions supporting the needs of engineers and downstream users throughout the product development lifecycle.

Creo enables a company’s digital transformation by providing a comprehensive suite of integral CAD/CAM/CAE and CAID solutions that support the needs of engineers and downstream users throughout the product development lifecycle.

Creo Benefits:

- Accelerate product innovation thereby getting better products to market faster.

- Seamlessly transition from the earliest phases of product design to manufacturing and beyond.

- Combine powerful, proven functionality with new technologies such as:

-

- Generative design

- Augmented reality

- Simulation

- Additive manufacturing

-

- Design faster, reduce costs and improve product quality.

- Delivers the transformative tools you need to build competitive advantage and gain market share.

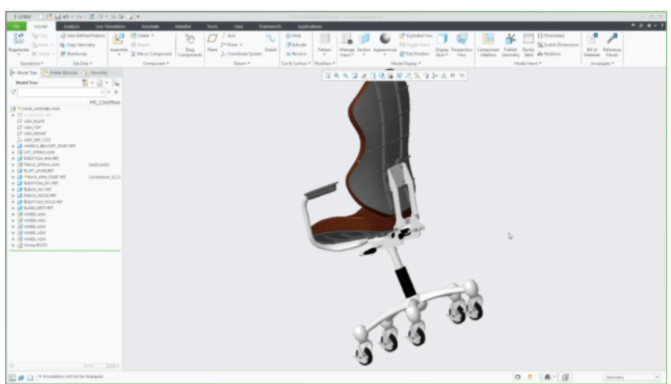

- Parametric Surfacing

- Freestyle Surfacing

- 2D Drawing

- Sheet Metal Design

- Mechanism Design

- Plastic Part Design

- Weld Design

- Fastener Design

- Design Exploration

- Routed Systems Design

- Human Factors Design

- Smart Connected Design

- Concept Design

- Industrial Design

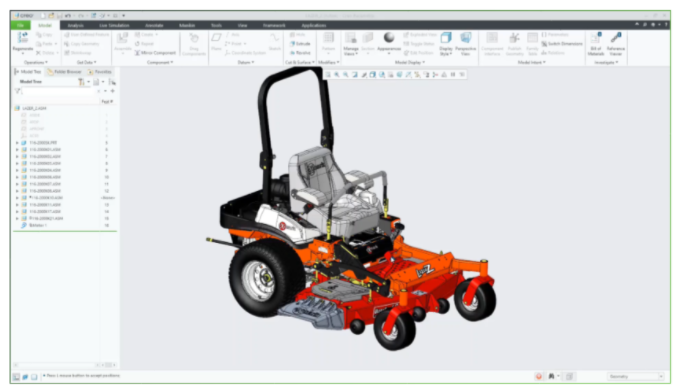

- Assembly Management & Performance

- Model-Based Definition (MBD)

- Multi-CAD

- 2D Drawing Creation

- 3D Model Annotation

- 3D Animation

- Rendering

- Augmented Reality

- GD&T Tolerance Analysis

- Additive Manufacturing

- Tool & Die Design

- Production Machining

- Technical Illustrations

PTC Digital Models Physical

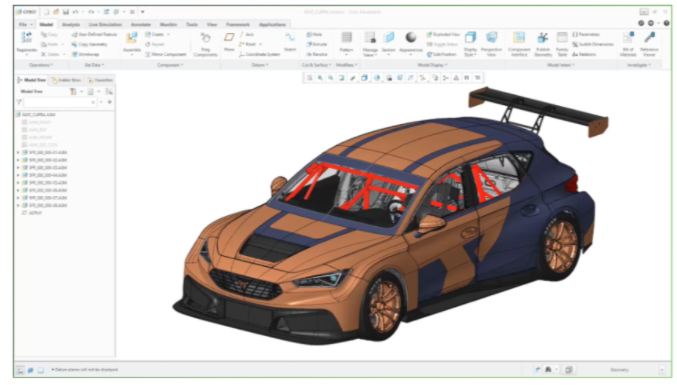

Sophisticated 3D modeling enables the creation of digital descriptions of physical products and communicates engineering innovation.

- Reduce design cycles by repurposing or radically transforming existing designs

- Rapidly iterate product designs to unlock opportunities for better products

- Accommodate design changes at any stage thus keeping the transition to manufacturing on schedule

- Increase engineering productivity by eliminating bottlenecks and delays via flexible design teams

- Leverage multi-source CAD data in the design process

- Move from 2D to 3D easily and/or switch from other 3D CAD systems

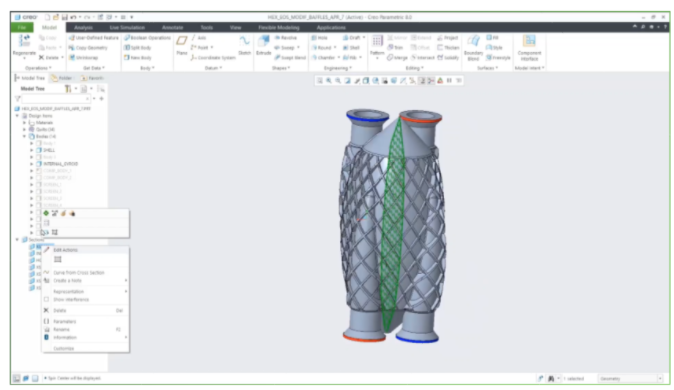

Artificial intelligence in generative design enables engineers to quickly evaluate dozens or hundreds of computer-generated design options, each specifically optimized for different materials and manufacturing methods.

- Define the model requirements and leverage the power of generative design

- Innovate with the creation of new parts and products

- Expert design options for analysis and selection

- Optimize design for manufacturing results

- Improve reliability

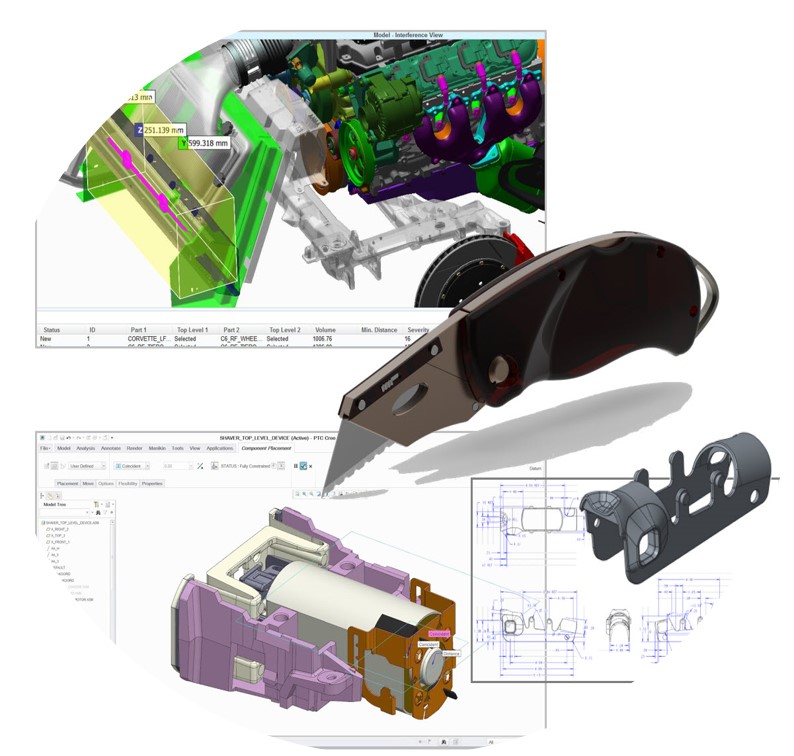

Real-time simulation helps engineers understand the ramification of every single change they make during the iteration process.

High-fidelity, high accuracy simulation capabilities are deeply integrated into Creo to quickly analyze models and validate designs.

- Deeper understanding of product performance

- Faster ramp-up, shorter development cycles and quicker time-to-market

- Reduced design-cycle times

- Fewer prototypes and first-time quality at reasonable cost

- Reduced warranty liability and exposure

- Deeper integration of simulation throughout the development process

Increase productivity and quality through more efficient machining and tool path design by extending the digital thread from engineering into manufacturing.

- Develop innovative designs

- Save on material waste and energy

- Reduce prototyping costs

- Enable part consolidation

- Faster time to market

Creo provides the ability to collaborate, share and communicate design information across the enterprise. Document and capture design and manufacturing requirements, create realistic product images for design review and create detailed assembly process planning documentation.

- AR Design Share – Easily create and securely share AR experiences managing models and viewer access

- Creo View – Powerful enterprise visualization technology that enables virtually effortless collaboration across local and global design teams

- Render Studio – Create realistic product images to evaluate design concepts, support design review, sales and marketing efforts

- Animation – Easily create assembly animations to demonstrate real-world behavior and assembly/disassembly instructions

- Assembly Process Planning – Streamline the creation of assembly process planning documentation

- Data Exchange – Easily integrate and work with standard formats and 3rd party data from CATIA V4/V5, SolidWorks, Siemens NX and Inventor

- 2D Detailing – Simplified creation and documentation of detailed manufacturing requirements

- 3D Annotations (MBD) – Define a single source of truth for design, manufacturing and process information

Essig Design through Manufacturing Solutions…

To learn more about Essig Engineering Services, contact info@essig.com.

To learn more about Essig Manufacturing Services, contact info@essigmfg.com.