Windchill benefits:

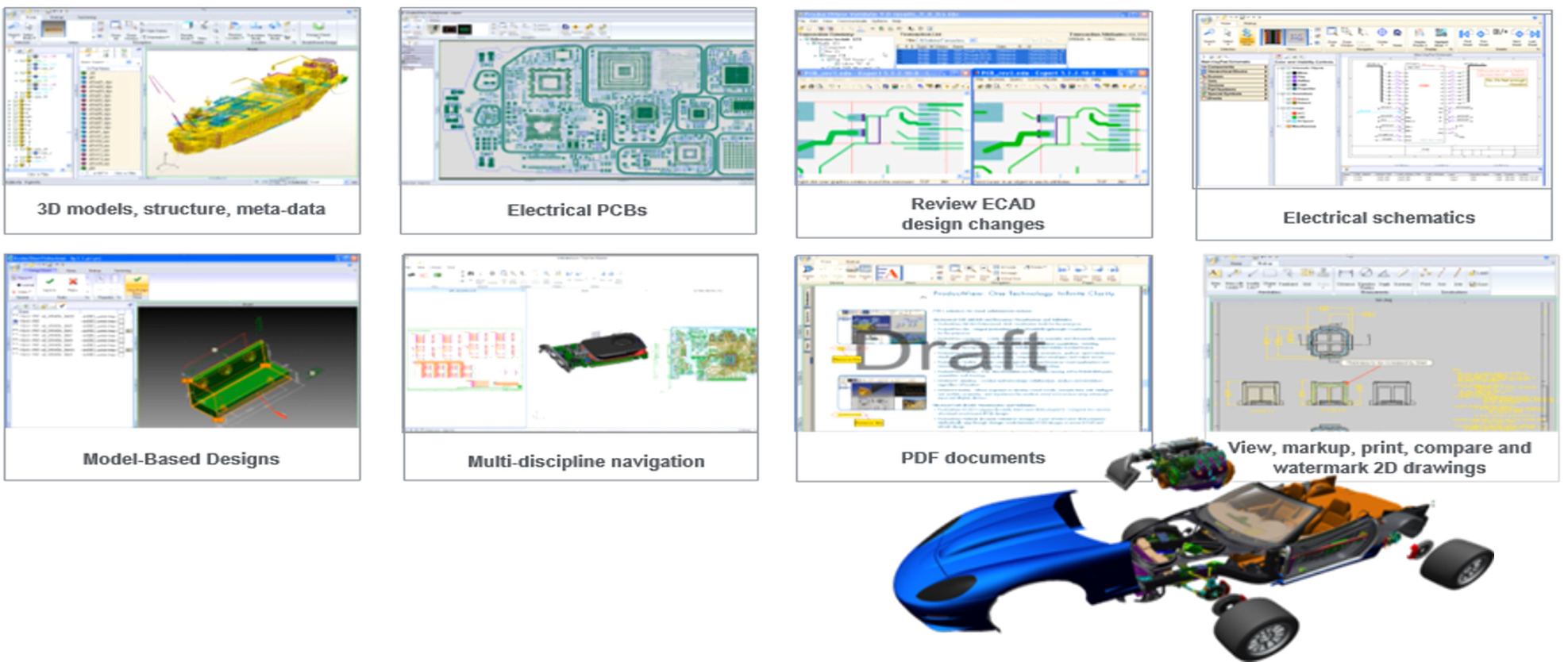

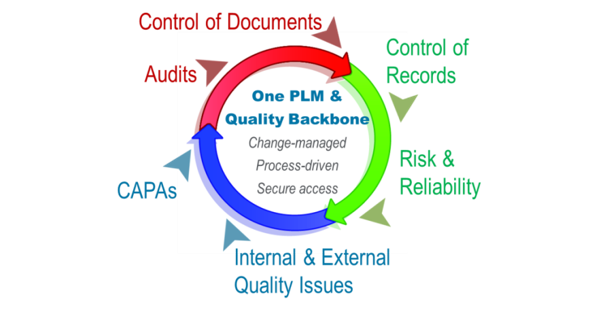

- Comprehensive out-of-the-box functionality

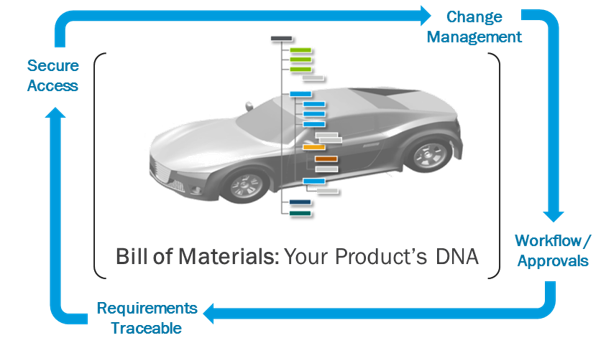

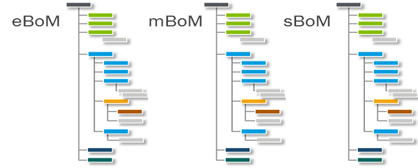

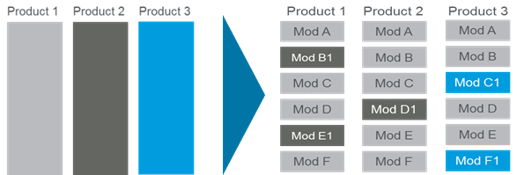

- Secure management of products and configurations

- Highly configurable role and task based applications

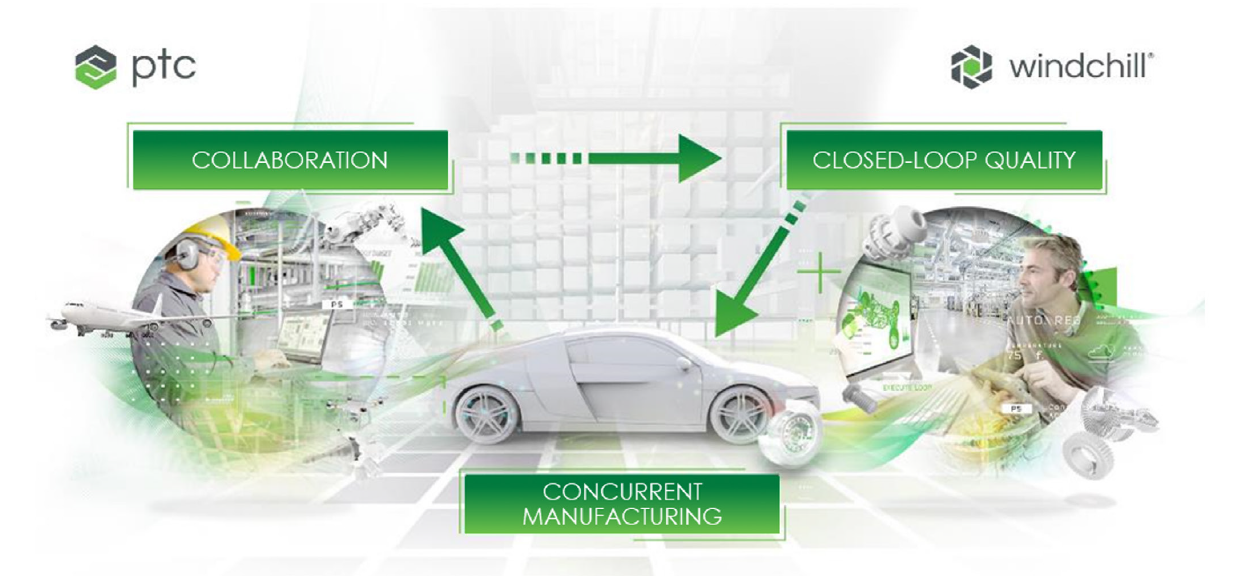

- Smart, connected enterprise foundation

- Digital thread

- Open architecture integrated with enterprise domain applications

Essig PLM has decades of experience working with customers to define their PLM strategy, execute requirements definition, and support the implementation and deployment.