Solutions

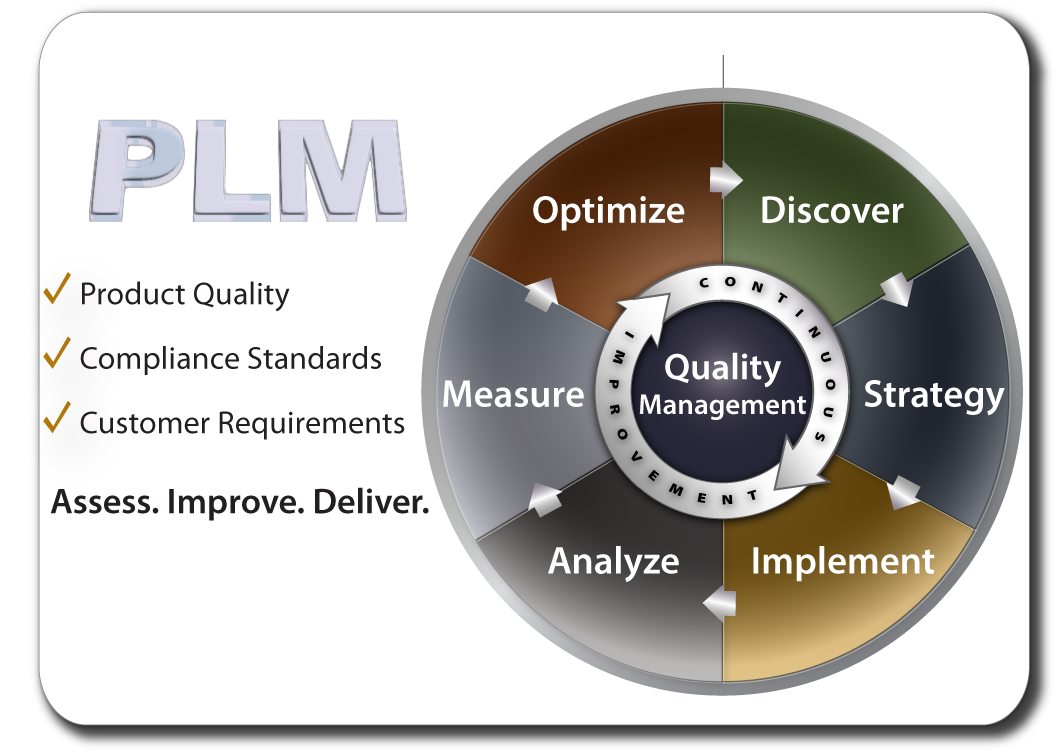

Quality Management

Quality Management in PLM provides visibility into critical information that allows organizations to be proactive and reactive. Implementing quality planning, corrective action, and root cause analysis accelerates the identification of issues, exposing potential defects before product release.

With PLM, companies are able to maintain consistent quality processes by coordinating reviews and facilitating communication throughout the concept, design and manufacturing lifecycles and processes.

PLM also provides the ability to manage libraries and critical quality documents such as DFMEA/PFMEA, PCP, PFD as well as Fault Tree Analysis, Fishbone, and Five whys.

Leveraging quality management within PLM allows companies to support quality standards including AS9100, FDA, QSR and others.

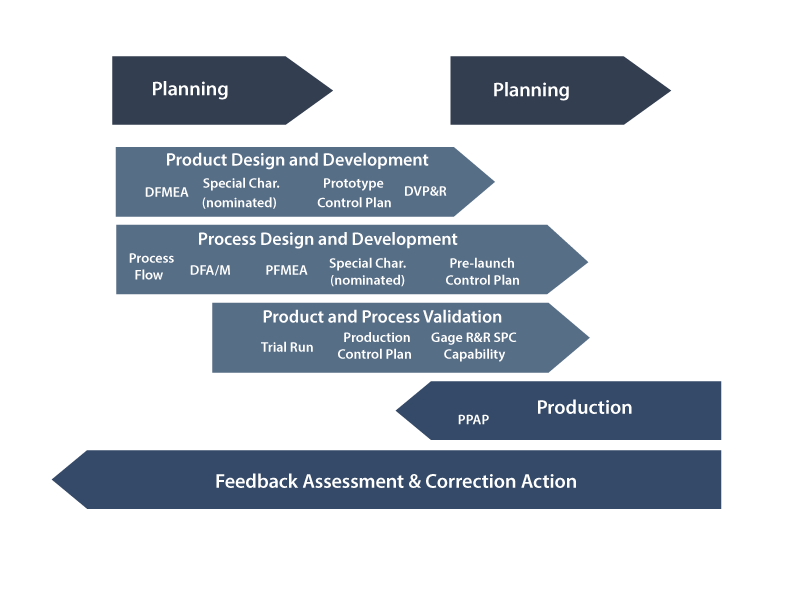

Advanced Product Quality Planning

PLM provides the mechanism for managing the Advanced Product Quality Planning processes and procedures to support planning and programs, product design and development, product manufacturing processes, testing and validation, and lastly the product launch and continuous improvement.

The ability to implement and manage closed-loop corrective action and root cause analysis provides early insight into issues and the ability to identify affected items before product release.

Creating, storing and maintaining all of the critical quality documentation within PLM enables visibility, collaboration and streamlines the processes related to improving product development and process planning across the enterprise.

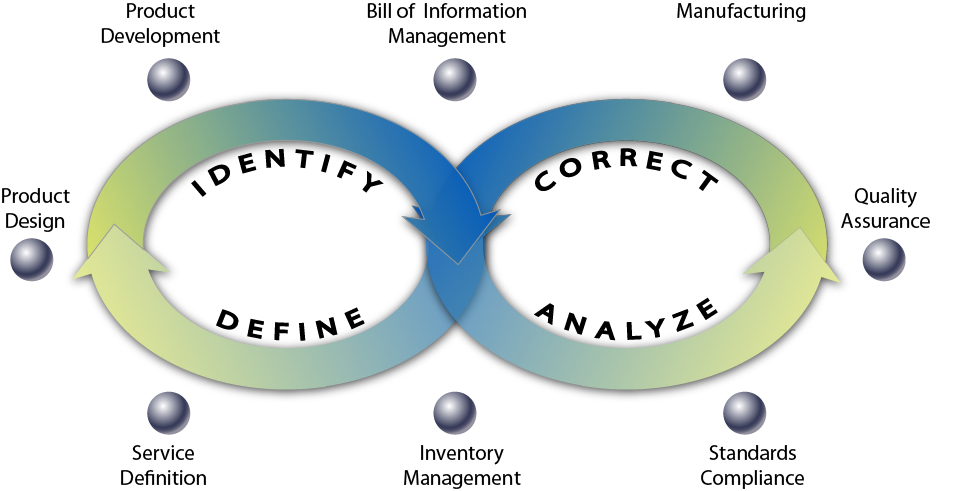

Closed-loop Corrective Action

PLM provides the framework and processes for coordinating the information flow involved in Closed-loop corrective action. CLCA within PLM ensures timely notifications and easy access and visibility to a secure database containing all of the relevant information such as serial numbers, descriptions, symptoms, reporting data, priority levels, solutions, status and resolution.

Case Study:

Freudenberg-NOK: Secrets to Eliminating Disparate APQP Systems with Aras

Read how Freudenberg-NOK achieves Advanced Product Quality Planning (APQP) compliance success and develops higher quality products faster with Aras Innovator.